Micro-vibrationisnot only the biggest problem, but also interferes with corporate profits, so to effectively improve and control micro-vibration is very important.

Micro-vibration measurement service

Micro-vibration measurement rationale:

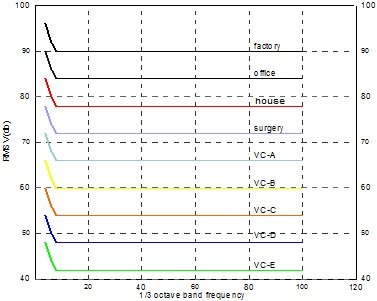

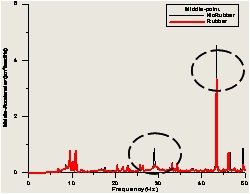

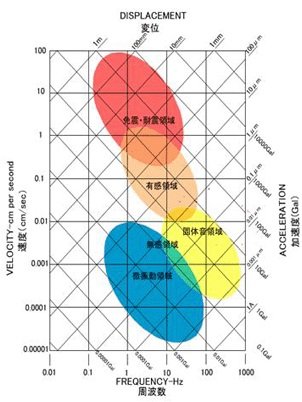

Sources of micro-vibration is quite complex and diverse. First, a precision measuring instrument is placed on the measuring point. Vibrations can be received horizontally and vertically at a measuring point. Signals can be analyzed in the time and frequency domain. From the time domain analysis can be obtained through peak amplitude, peak to trough amplitude, and the RMS amplitude and other physical quantities. Frequency domain analysiscan be analyzed from the time domain and converted. The amount of vibration and BBN vibration specifications (Colin G. Gordon) are compared in order to understand the vibration of the floor.

| Critical curve | Max. Level | amplitude | Description of Use | ||||

| Micro-inches/sec | Micro-mches/sec | DB | |||||

| Workshop | 32000 | 800 | 90 | N / A | Workshop and non-sensitive areas | ||

| Office | 16000 | 400 | 84 | N / A | Appropriate for offices and non-sensitive areas | ||

| Residential Day | 8000 | 200 | 78 | 75 | Appropriate to sleep. Probably adequate for computer equipment, probe testing and low-power (to 20x) microscopes. | ||

| Op. Theatre | 4000 | 100 | 72 | 25 | Suitable for sensitive sleep areas. Suitable in most instance for microscopes to 100x and equipment of lower sensitivity. | ||

| VC-A | 2000 | 50 | 66 | 8 | Optical microscopes to 400x. | ||

| VC-B | 1000 | 25 | 60 | 3 | Optical microscopes to 1000x, and lithograph equipment to 3 micron line width. | ||

| VC-C | 500 | 12.5 | 54 | 1 | Lithograph equipment to 1 micron line width. | ||

| VC-D | 250 | 6 | 48 | 0.3 | Electron microscopes (TEMs, SEMs) and E-Beam systems. | ||

| VC-E | 125 | 3 | 42 | 0.1 | For the most demanding of sensitive systems including long-path laser-based, small target systems. | ||

FAB Vibration Standard

Machine vibration specifications

Machine vibration source

Vibration control

FAB Machine vibration control

Vibration-isolated foundation

Scanner basic measures

Micro-vibration

Colin G. Gordon” Common Criteria vibration sensitive equipment”

Assess the surrounding environment and other internal vibrations

Effect of process tools

SEM (Scanning Electron Microscope):Horizontal vibration - display blurring.

FIB (Focused Ion Beam):Horizontal vibration - machining errors, display blurring.

Stepper/Scanner:Stepper/Scanner: Horizontal vibration - Visual errors, display blurring.

EB (Electron Beam):Horizontal vibration - machining errors.

Film Thickness:Vertical vibration - measurement accuracy is reduced.

One-Third Octave Band Spectral Dat

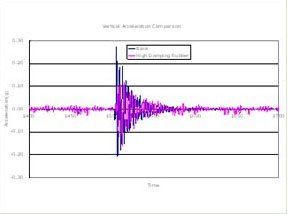

Vertical Hammer Test